发布者: 中国重型机械工业协会 发布时间:2024-02-29阅读次数:454

世界上最宽规格(2680mm)的不锈钢热连轧生产线

——2023年重型机械世界之最科技成果获奖项目专题报道

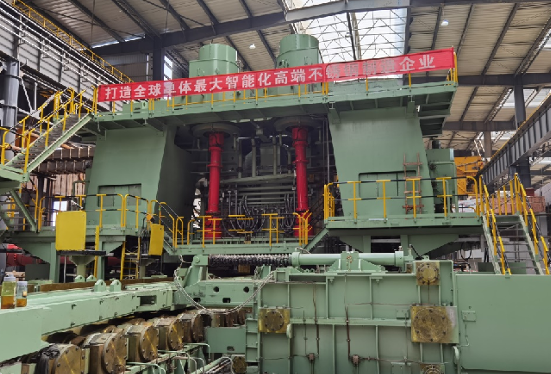

获奖项目:2680mm宽幅不锈钢热连轧生产线

首次投运时间:2022年4月

研制单位:1.中国第一重型机械股份公司 www.cfhi.com,2.一重集团大连工程技术有限公司

联系人:马博,13591107893 ,93636619@qq.com

该项目实现了高端宽幅不锈钢热连轧生产线工艺及装备等核心技术从无到有的突破,自主设计制造了世界上最宽规格溧阳德龙2680mm不锈钢热轧生产线。

其创新成果有:

1.首创“1+8”宽幅不锈钢热连轧生产线工艺配置,开发了高精度分配策略、温度模型、力能模型,构建了全流程模拟分析系统与工艺优化技术,实现了多品种、多规格不锈钢热轧产品高效稳定生产以及厚度与宽度极限突破。

2.开发出新型精轧机工作辊弯辊横移等装置,实现了宽幅不锈钢薄带热连轧成套装备自主设计开发与绿色化应用示范。

3.研发出融合机理模型、生产数据与深度学习算法的不锈钢热轧生产线与工艺参数设计软件,开发出辊型曲线设计优化系统,实现热连轧生产线总体布局、设备配置、参数优化等数字化与智能化控制。

经鉴定,项目总体技术达到国际先进水平,在“1+8”热连轧工艺技术、弯窜辊装置及板形调控方面达到了国际领先水平。

成果成功应用于溧阳德龙、鼎信印尼等8条不锈钢生产线,占据国内同类设备市场90%以上。

The widest stainless steel hot strip rolling line in the world

2680mm Wide Stainless Steel Hot Continuous Rolling Line

1.China First Heavy Industries Corporation ,www.cfhi.com

2.CFHI Dalian Engineering &Technology Co.,Ltd.

The project has achieved a breakthrough in core technology of high-end wide-width stainless steel hot rolling production line process and equipment from scratch, and independently designed and manufactured the world's widest Liyang Delong 2680mm stainless steel hot rolling production line.

Its innovation achievements are as follows:

1.Created the first "1+8" wide stainless steel hot rolling production line process configuration, developed high-precision distribution strategy, temperature model, force and energy model, constructed the whole process simulation analysis system and process optimization technology, and realized multi-variety, multi-specification stainless steel hot rolling products efficient and stable production and thickness and width limit breakthrough.

2.Developed a new type of finishing mill work roll bending and transverse rolling device, and realized the independent design and development of complete equipment of wide-width stainless steel thin strip hot strip rolling and green application demonstration.

3.Developed a stainless steel hot rolling production line and process parameter design software that integrates mechanism model, production data and deep learning algorithm, and developed a roll shape curve design optimization system,and realized the overall layout, equipment configuration, parameter optimization and other digital and intelligent control of the hot rolling production line.

After identification, the overall technology of the project has reached the international advanced level, and it has reached the international leading level in the "1+8" hot continuous rolling process technology, work roll bending and traversing device and plate shape control.Results successfully applied to 8 stainless steel production lines such as Liyang Delong and Dingxin Indonesia, occupying more than 90% of the domestic similar equipment market.