发布者: 中国重型机械工业协会 发布时间:2024-03-01阅读次数:498

世界上起重量最大(20000t)的桥式起重机

——2023年重型机械世界之最科技成果获奖项目专题报道

设备/技术名称:20000t×125m多吊点桥式起重装备

研制单位:大连华锐重工集团股份有限公司 www.dhidcw.com

首次投运时间:2008年1月

联系人:祝馨筠,13322215837 ,zhuxjb@dhidcw.com

2万吨多吊点起重装备主要担负船坞作业范围内的平台起升、对接工作。设有12套卷扬机构、48个吊点,分别布置在两根主梁下方。其中靠近坞门侧主梁上卷扬起升高度113m;另一侧主梁上卷扬起升高度83m,为满足不同设备吊点位置的不同,该主梁还具有水平横移±7m的功能。该设备跨度125m,主梁高度18m、宽度4.8m。

该起重机是当今起重量最大的桥式起重设备,多项核心技术为世界首创:首创了第一个高低梁桥式起重机,并采用了超大型复合式主梁结构,最大限度减轻自重;发明了主梁平移机构专利技术;首创了大倍率起升机构效率补偿装置;自主开发多起升机构电气控制软件;首创超大主梁分段陆地制造、水中驳船上整体合拢焊接技术。

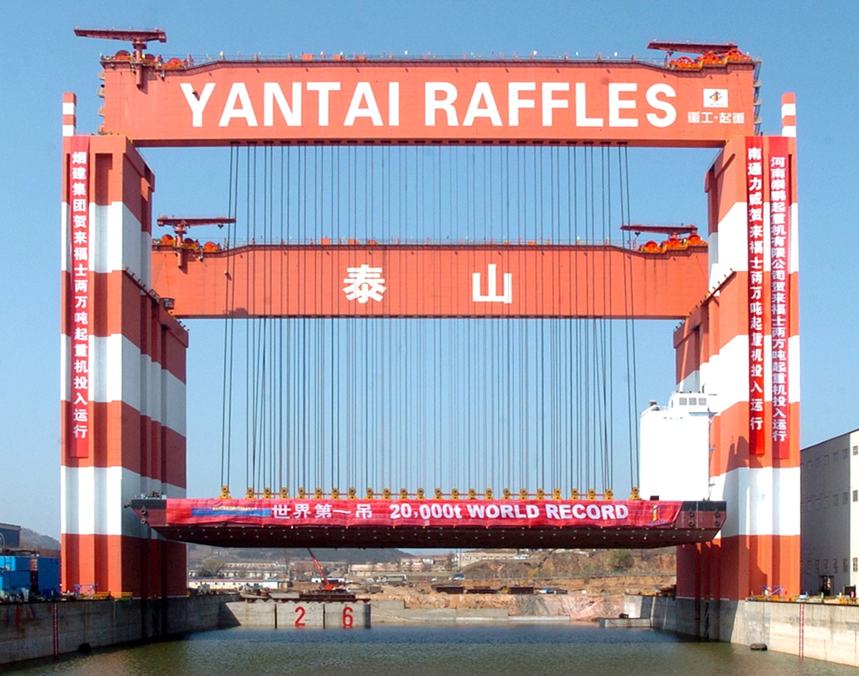

该设备用于烟台中集来福士海洋工程有限公司,能够实现2万吨以内海洋平台整体一次性平稳吊装,改变了传统海洋平台坞内小分段制造工艺,单次吊装可节省约200万个工时,建造周期缩短30%,降低了制造成本。

上图:吊装钻井平台

下图:交机现场带载荷吊装

The world's largest overhead crane by lifting capacity (20,000 tons)

20000t×125m multiple hanging point crane

DALIAN HUARUI HEAVY INDUSTRY GROUP CO.,LTD

www.dhidcw.com

The 20000tmultiple hanging point crane is mainly responsible for the platform lifting and docking work within the scope of dock operation. There are 12 sets of hoist structures and 48 lifting points, which are arranged under the two main beams. Among them, the main beam near the dock gate is raised up with beam also has the function of horizontal and transverse movement of ±7m. The span of the equipment is 125m, the height of the main beam is 18m, and the wider is 4.8m.

The crane is the largest lifting weight of the bridge lifting equipment, a number of core technologies for the world’s first: the first high and low beam bridge crane, and the use of large composite main beam structure, minimize the weight; Invented the main beam translation mechanism patent technology; The efficiency compensation device of large rate lifting mechanism was first developed. Independent development of multiple lifting mechanism electrical control software; First large main beam segment on land manufacturing ,water barge on the whole closing welding technology.

The equipment is used in Yantai CIMC Raffles Marine Engineering Co.,LTD., which can achieve a one-time and stable lifting of the entire offshore platform within 20000t, changing the traditional offshore platform dock small segment manufacturing process, a single lifting can save about 2 million hours, shorten the construction cycle by 30%, and reduce the manufacturing cost.